KOINJAYA provides a testing and certification company with a mobile test unit. All inspections take place in the ON-SITE., so that the customers can immediately assess the testing themselves. The testing company certifies the kit and all the other equipment that qualify for inspection. After each inspection the certificates are given digitally however these certificates together with the final report that the inspectors goes through with the customer can also be printed on certificate paper.

Besides the fire brigade inspections Rusch Inspections is also very active within the industrial sector (metal and refuse disposal plants) and in the municipalities. Industrial parks and shipyards are often located in the immediate vicinity of fire departments. The Rusch inspections of hoisting and lifting tools: NEN 3140 inspection, sawing and pruning equipment and all other work equipment, link up with each other perfectly. All the work we do can be found on our website next to the fire brigade icon. Our digital catalogue, in which all the resources in the field of lifting and hoisting equipment can be found, is on the site as well. The material is divided into product groups and specifications.

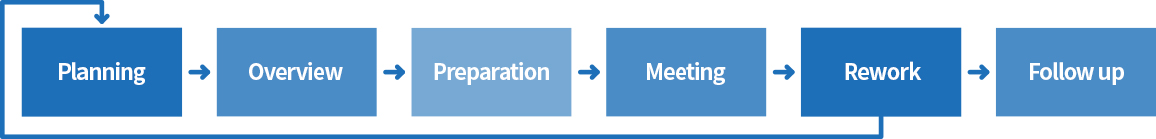

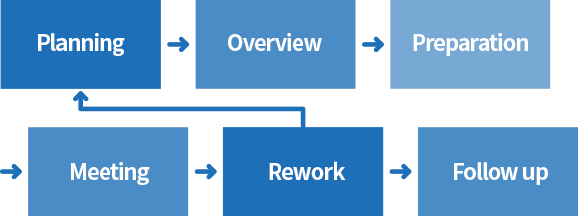

Planning

- Preparation of materials

- Arranging of participants

- Arranging of meeting place

Overview

- Group education of participants on the materials under review

- Assignment of roles

Preparation

- The participants review the item to be inspected and supporting material to prepare

for

the meeting noting any questions or possible defects

- The participants prepare their roles

Inspection meeting

- Actual finding of defect

Rework

- Rework is the step in software inspection in which the defects found during the

inspection

meeting are resolved by the author, designer or programmer. On the basis of the list of defects the

low-level document is corrected until the requirements in the high-level document are met.

Follow-up

- In the follow-up phase of software inspections all defects found in the inspection

meeting

should be corrected (as they have been fixed in the rework phase). The moderator is responsible for

verifying that this is indeed the case. He should verify if all defects are fixed and no new defects

are

inserted while trying to fix the initial defects. It is crucial that all defects are corrected as

the

costs of fixing them in a later phase of the project wil l be 10 to 100 times higher compared to the

current costs.

- All inspections take place in the fire station.

- Direct assessment of inspections by the

customer.

- Fully equipped test vehicle in which all testing and repairs are carried out

directly.

- The certificates are instantly processed and made.

- In case of a fire alarm there

is

immediate access to a vehicle.

- After each inspection, you will receive a folder containing the

processed final report.

- Parts needed for repairs are immediately available from stock.

In recent years there has been considerable interest in safety, health and welfare during work. With the health and safety legislation the government wants to reduce absence from work due to sickness.

The occupational health and safety law requires employers to pursue a work conditions policy, in which personalized care comes first. Measures should be adapted to the risks present, in particular with the safety of personnel. Accidents must of course be reduced as much as possible. To achieve this, the law states that the employer is responsible for periodic and expert inspections. Maintaining work equipment also could prove to be necessary here and be added to the inspection.

Equipment for working with height difference

Within our KOINJAYA work regulations equipment

comes

under the fall protection apparatus of personal protective equipment . KOINJAY is accredited by

Petzl

except for fall arrest blocks. Depending on the brand the annual inspection is taken care of in

consultation with the manufacturer.

Climbing and scaffolding equipment

- Inspection of sliding, push-up and single ladders according

to

EN-1147.

- In addition there are ladders and stairs in accordance with NEN 2484 and in

height-adjustable work loading platforms / work landings.

Sawing and pruning equipment

- Inspection of the safe operation of the motor chainsaw

PrEN-608

-

Safety helmet with face screen and ear muffs d ear muffs

There is quite a bit of difference. Along with our quality, professional inspections, we feel our

detailed inspection reports set us apart.

These reports are provided on each piece of equipment that we inspect.

We are one of just a few agencies that provide their customers with such detailed paperwork.

Unlike the simple, one-page handwritten checklist that you may have received from other companies,

every

crane that we inspect has its own folder containing a detailed inspection report with applicable

regulations referenced that are Korean safety rule compliant.

Experience has taught me that the customer needs more than a simple, handwritten sheet statingthat something needs to be corrected. The customer needs to know specifically which regulation is being quoted.

Crane Inspection Services, Inc . has been very fortunate to serve some large clients nationwide. The

detailed inspection reports have helped middle-management justify the allocation of necessary funds

needed to make repairs.

This detailed documentation has been a terrific selling point to most companies across the

nation.

We are probably the only company that has all of the current regulations on computer that are

applicable

to cranes in the general industry, construction, maritime, and long shoring areas.

If your company is sincere in its efforts to encourage safety, this will be a great benefit to you.

Another important benefit of using Crane Inspection Services, Inc. is the promptness with which you

will

receive the completed folders. In most cases, the customer is given the documentation at the

completion

of the job. We literally complete our paperwork at your job site so that you can see where your

money is

being spent. In some cases, more time may be necessary to complete the paperwork, but never more

than 7

days from the completion date of the job. We pride ourselves on our timeliness and look forward to

the

opportunity of serving you.